The Essential Beginner Tool Kit

Walk into a woodworking store or browse online catalogs and you’ll find thousands of tools. Beginners often wonder which ones they actually need. The answer is fewer than you’d think. Five core tools handle the majority of beginning projects.

Tool #1: A Good Handsaw

Every woodworking project starts with cutting wood to size. A quality handsaw costs far less than a table saw and teaches fundamental technique. Start with a general-purpose crosscut saw, about 12-15 points per inch.

Japanese pull saws have gained popularity for good reason. They cut on the pull stroke, creating thinner kerfs and requiring less force. A ryoba with crosscut teeth on one side and rip teeth on the other covers most sawing needs.

Learn to saw straight before investing in power tools. The skill transfers directly. Understanding how saws cut makes you better at using any saw, hand or power.

Tool #2: A Combination Square

Accurate measurement and layout underpin all woodworking. A combination square measures, marks 90-degree and 45-degree angles, checks flatness, and sets depth gauges. One tool, many functions.

Buy quality here. A cheap combination square that’s not actually square wastes more in ruined cuts than the money saved. Starrett, PEC, and iGaging make reliable options at various price points.

Use the square constantly. Check every cut. Verify every joint. Developing the habit of checking square prevents countless errors.

Tool #3: A Block Plane

A small block plane fits in one hand and adjusts wood surfaces in ways sanders can’t match. Ease sharp edges, trim end grain, fit joints, clean up saw cuts. The block plane handles all these tasks quickly and quietly.

Standard-angle block planes work for general use. Low-angle versions excel at end grain but work everywhere. Either serves beginners well. More important than angle is keeping the blade sharp.

Learn to sharpen. A dull plane frustrates users into giving up. A sharp plane makes work enjoyable. Sharpening takes practice but rewards the effort with better results and faster work.

Tool #4: A Set of Chisels

Chisels pare joints, chop mortises, clean up corners, and carve details. A basic set of four—1/4″, 1/2″, 3/4″, and 1″—handles most situations. Add more sizes as specific needs arise.

Budget chisels work fine for beginners. Expensive Japanese chisels perform beautifully but require advanced sharpening skills to maintain. Start modest, upgrade as skills develop.

Keep chisels sharp and stored safely. Blade contact damages edges quickly. A simple tool roll or wooden rack protects your investment.

Tool #5: Clamps

You can never have too many clamps, but you can certainly have too few. Start with at least four bar clamps in the 24-36 inch range. Add a handful of spring clamps for quick holding tasks.

F-style clamps offer good value for general clamping. Parallel-jaw clamps apply more even pressure but cost more. Quick-release mechanisms speed work once you’re using clamps frequently.

More clamp variety comes later: pipe clamps for large panels, corner clamps for box assembly, hold-down clamps for bench work. The basic bar clamps handle most beginning projects.

What About Power Tools?

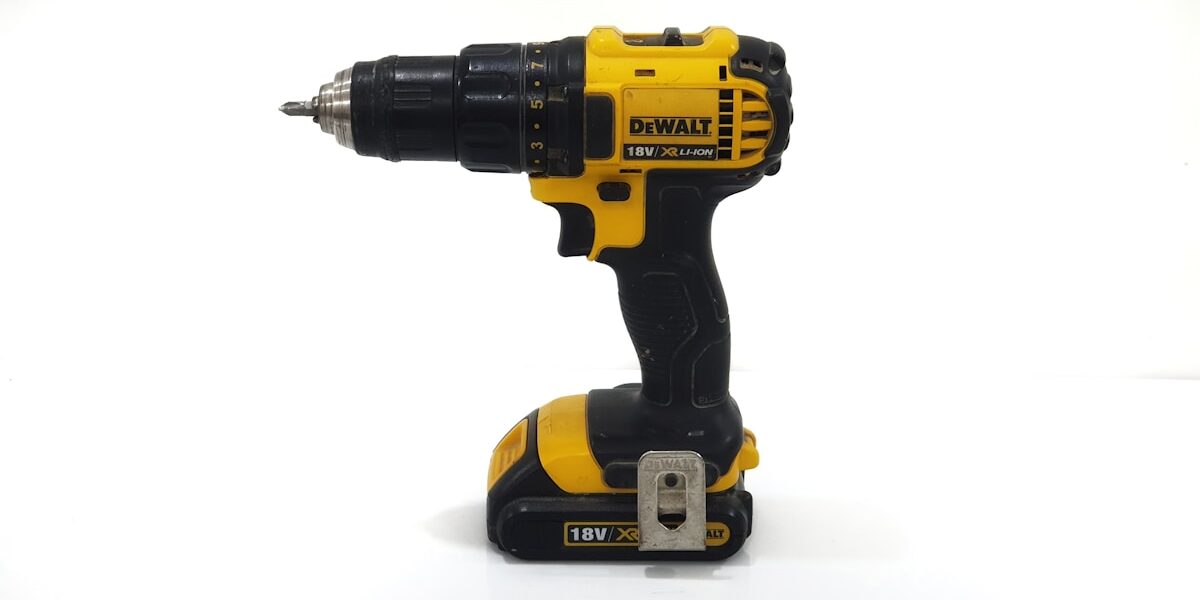

Power tools aren’t wrong; they’re just not essential for starting out. A cordless drill helps with many projects. A jigsaw cuts curves. A random orbit sander speeds surface preparation.

But beginners often buy power tools before learning the underlying skills. The table saw doesn’t teach you how wood behaves. The thickness planer doesn’t reveal grain direction. Hand work builds understanding that makes power tool use safer and more effective.

Consider power tools as you identify specific needs. The right tool depends on the projects you build and the methods you prefer. Let experience guide purchases rather than buying everything upfront.

Measuring and Marking

Beyond the combination square, a tape measure handles rough dimensioning. A marking knife creates cleaner lines than pencils for precision work. A marking gauge scribes parallel lines for joinery layout.

Add these as the combination square’s limitations become apparent. The square handles most beginning measurement needs. Specialized marking tools enhance precision as skills develop.

Sharpening Equipment

Sharp tools require sharpening equipment. A basic setup includes a sharpening stone (synthetic waterstones work well), a honing guide for consistent angles, and a strop for final polish.

Learn to sharpen early. The skill matters for every edged tool you’ll own. Dull tools require excessive force, produce poor results, and increase injury risk. Maintaining edges prevents all these problems.

Workholding

You need to secure work for sawing, planing, and chiseling. A simple workbench with a vise handles most needs. Alternatively, bench hooks, shooting boards, and sawing benches provide specific solutions without a full workbench.

Improvisation works for beginners. Clamp boards to any sturdy table. Build simple jigs as needed. Proper workholding develops as you understand what your work requires.

The Total Investment

A quality saw, combination square, block plane, chisel set, and basic clamps cost under $200 together if chosen carefully. That’s enough to build useful projects while developing fundamental skills.

Resist the urge to buy everything at once. Each project reveals tool needs more clearly than any buying guide. Purchase what the work requires when the requirement becomes clear.

Growing Your Kit

After building several projects with basic tools, patterns emerge. You’ll know whether you need more clamps or better sawing equipment. You’ll understand which operations consume the most time and might benefit from specialized tools.

Woodworking tool collections grow over lifetimes. There’s no rush. Start with the essentials, build projects, and let experience guide your tool choices. The tools you actually need reveal themselves through work.